There are many different types of cable jackets and each jacket works well in a specific application. The three main sensor cable jackets are PVC (Polyvinyl Chloride), PUR (polyurethane) and TPE (thermoplastic elastomer). Each jacket type has different benefits like washdown, abrasion resistant or high flexing applications. Finding the correct jacket type for your application can extend the life of the cable.

Katlax use this cables for making M8 , M12 and various type of wiring harness.

The following answers to some of the top cable questions can help you select the right cable for your application.

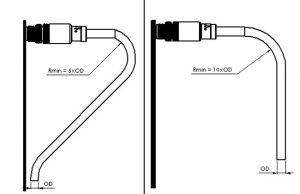

Bend Radius

Bend radius refers to smallest curve that a cable may have when laid without changing the characteristics of the cable. Bend radii [Rmin] are specified in relation to the cable diameter.

Halogen-free mean

Cables and wires are defined as halogen-free if they are made of materials that do not contain salt forming chlorine, fluorine, bromine and iodine. The insulation and cladding of these cables are made of polymers based on pure hydrocarbons. When these materials burn, only water vapor and carbon dioxide are emitted [no corrosive or toxic gases].

The use of halogen-free cables becomes more and more compulsory with increasing numbers of buildings where safety consciousness to protect humans and valuable materials take a special significance including hospitals, airports, hotesl, theatres, schools and more.

PVC Cables

PVC is a general purpose cable and is widely available. It is a common cable, and typically has the best price point. PVC has a high moisture resistance, which makes it a good choice for wash-down applications.

Pure PVC cables are suitable for medium mechanical stress for packaging machine applications as well as assembly and production lines. PVC cables have good resistance to acid and alkalis and therefore are ideally suited for use in the food and beverage industry. PVC cables have limited abrasion behavior and limited resistance to oil and chemicals.

PUR Cables

A PUR cable is a flexible. This cable jacket type has good resistance against abrasion, oil and ozone. PUR is known for being Halogen free, not containing: chlorine, iodine, fluorine, bromine or astatine. It is oil and flame resistance and can be used in dgrachain applications with minimal bend radius. PUR cables are very well suited for flexible applications in robotics machine tools and metal cutting manufacturing. This jacket type does have limited temperature range compared to the other jacket types, -40…80ºC.

When should I use PUR cables?

Various industries, e.g. machinery, plant or tool-making industries are working particularly with mineral oils, alkalis and aggressive coolant emulsion and under difficult environmental working condition. Due to these conditions, the electrical cables have to perform to exceptionally high standards. When flexibility, abrasion and oil resistance have to be guaranteed, choose PUR cables!

TPE Cables

TPE is flexible, recyclable and has excellent cold temperature characteristics, -50…125⁰C. This cable is resistant against aging in the sunlight, UV and ozone. TPE has a high-flex rating, typically 10 million.

The table below details the resistance to different conditions. Note that these relative ratings are based on average performance. Special selective compounding of the jacket can improve performance.

| Resistance to : | PVC | PUR | TPE |

| Oxidation | Excellent | Excellent | Outstanding |

| Heat | Good-Excellent | Excellent | Outstanding |

| Oil | Fair | Outstanding | Outstanding |

| Low Temperature Flexibility | Poor-Good | Excellent | Outstanding |

| Weather, Sun | Good-Excellent | Excellent | Outstanding |

| Ozone | Excellent | Excellent | Excellent |

| Abrasion | Fair-Good | Excellent | Excellent |

| Electrical Properties | Fair-Good | Excellent | Excellent |

| Flame | Excellent | Excellent | Outstanding |

| Nuclear Radiation | Fair | Excellent | Poor |

| Water | Good-Excellent | Good-Excellent | Excellent |

| Acid | Good-Excellent | Excellent | Excellent |

| Alkali | Good-Excellent | Excellent | Excellent |

| Gasoline | Poor | Excellent | Excellent |

| Benzol | Poor-Fair | Excellent | Excellent |

| Degreaser Solvents | Poor-Fair | Excellent | Excellent |

| Alcohol | Good-Excellent | Excellent | Excellent |

| Weld Slag | Fair | Excellent | Excellent |

Choosing the right jacket type can help reduce failures in the field, reducing downtime and costs.